Kab ntau lawm tsis siv neeg 1-5L lub voos xwmfab

Kab ntau lawm tsis siv neeg 1-5L lub voos xwmfab

Kev Tsim Yeeb Yaj Kiab

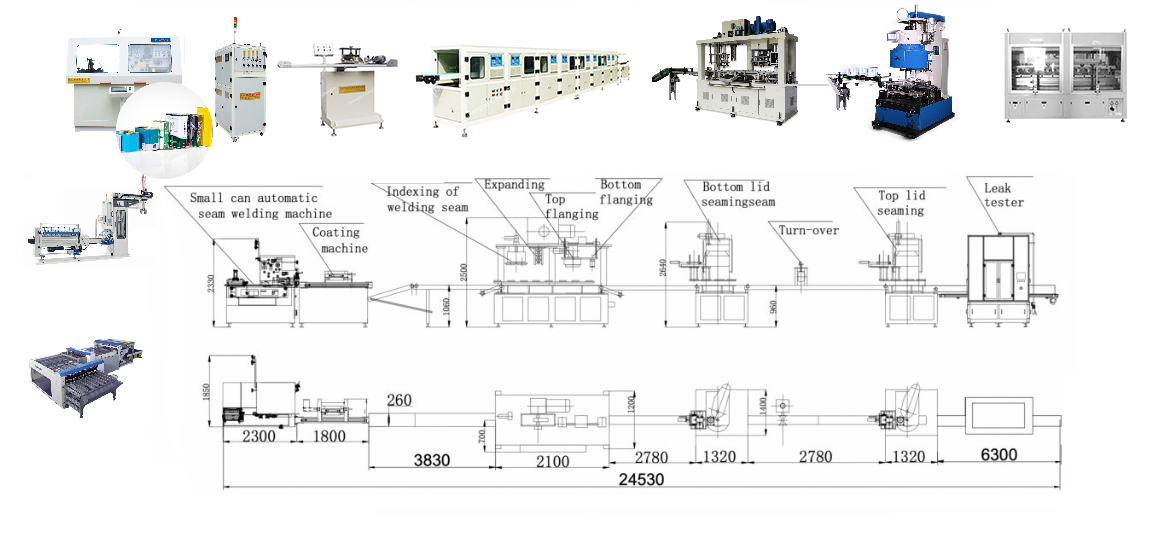

LubKab ntau lawm ntawm 1-5L lub thawv plaub fab tsis siv neegyog tsim rau kev tsim khoom tsis siv neeg ntawm 1-5L rectangular can.

Cov tshuab yoghloov kho tauraws li koj cov kaus poom loj thiab cov kev xav tau thev naus laus zis, xws li lub kaw lus hloov pauv, conveyor thiab palletizing system tuaj yeem raug tshem tawm.

Cov txheej txheem ua haujlwm yooj yim

1. Muab qhovtxiav cov khoom siv lub cevrau hauv lub tshuab vuam tsis siv neeg lub rooj pub mov, Nqus los ntawm cov tshuab nqus tsev, xa cov tin blanks mus rau lub menyuam pub mov ib qho los ntawm ib qho.through lub menyuam pub mov, ib lub tin blank yog pub rau lub menyuam sib npaug kom ua cov txheej txheem sib npaug, tom qab ntawd nws yuav raug pub rau lub tshuab sib npaug los ua kom sib npaug.

2. Lub cev raug pub rau hauv kev tiv thaivtshuab vuamthiab ua vuam tom qab qhov chaw raug.

3. Tom qab vuam, lub cev muaj peev xwm tau pub rau hauv lub tshuab xa khoom sib nqus ntawm lubtshuab txheejrau txheej txheej, txheej sab hauv lossis txheej hmoov sab hauv, Uas nyob ntawmcov neeg siv khoom xav tau ntau yam. Nws yog siv los tiv thaiv covkab vuam sablos ntawm kev raug rau hauv huab cua thiab xeb.

4. Lub cev muaj peev xwm ces pub rau tus me melub tshuab ua ke rectangular, thiab lub cev muaj peev xwm nyob rau hauv ib lub xeev ncaj nraim mus los ntawm lub tshuab nqa khoom ncaj nraim. Nws yog pub rau thawj qhov chaw vuam seam indexing chaw nres tsheb los ntawm cov clamps.

5. Qhov chaw nres tsheb thib ob yogkev nthuav dav ntawm lub duab plaub fabThaum lub cev muaj peev xwm nyob rau hauv txoj haujlwm, ntawm lub cev muaj peev xwm nqa lub tais uas tswj hwm los ntawm lub cev muaj zog servo, thiab lub cev muaj peev xwm raug xa los ntawm lub tais nqa no mus rau lub pwm nthuav dav kom ua rau lub cev muaj peev xwm nthuav dav.

6. Qhov chaw nres tsheb thib peb yog ua komlub cev qis dua flange.Qhov flange hauv qab: lub kaus poom yuav raug xa mus rau qhov pwm flange qis dua uas pw rau sab saud ntawm lub tshuab los ntawm kev tsa lub tais kom ua rau nws.

7. Qhov chaw nres tsheb thib plaub yog ua komlub cev muaj peev xwm flange sab saud. Lub flange sab saud: lub tog raj kheej sab saud yuav nias lub cev tuaj yeem mus rau qhov chaw ntawm lub pwm flange sab saum toj kom ua rau nws. Ob lub flange sab saud thiab qis dua tuaj yeem yog txhua tus tsav los ntawm plaub lub tog raj kheej.

8. Qhov chaw nres tsheb thib tsib yogtsis siv neeg seaming hauv qabTom qab tsib kauj ruam saum toj no, lub cev tuaj yeem yuav raug thim rov qab los ntawm lub cev tig rov qab ces ua rau sab saum toj seaming, cov txheej txheem no zoo ib yam li cov txheej txheem seaming hauv qab.

Thaum kawg, lub tiav lawm tau pub los ntawm conveyor mus rauchaw kuaj xyuas qhov xau tsis siv neegTom qab kev tshuaj xyuas qhov chaw cua kom raug, cov khoom tsis tsim nyog raug kuaj pom thiab thawb mus rau thaj chaw ruaj khov, thiab cov khoom tsim nyog yuav tuaj rau ntawm lub rooj ua haujlwm ntim khoom rau qhov ntim kawg.

Cov Khoom Siv thiab Cov Txheej Txheem Tech-Parameter

Lubob lub tshuab slitter hlau or tshuab slitter tinplateyog ib qho ntawm cov khoom siv tseem ceeb tshaj plaws hauv kev lag luamKab tsim khoom 3-daim thoob.Nws yog thawj qhov chaw nres tsheb ntawm kab ua cov kaus poom. Nws yog siv los txiav cov ntawv tinplate lossis cov ntawv hlau tsis xeb raws li cov qhov loj me lossis cov strips rau cov kaus poom kawg. Cov duplex slitter zoo yog qhov kev vam meej thawj zaug hauv kev daws teeb meem zoo tshaj plaws rau lub Hoobkas ntim hlau. Ntau yam, Precise thiab Robust yog cov kev cai yooj yim rau duplex slitter.

Lub tshuab txiav muaj lub tshuab pub mov, lub tshuab txiav, lub thawv tswj hluav taws xob, lub twj tso kua mis, lub tshuab thauj khoom thiab lub tshuab ntse. Lub tshuab txiav ntau yam muaj ntau yam uas nws tuaj yeem pub tau yam tsis tas siv neeg,ntsug, kab rov tav txiav tau, kev tshawb pom duplex thiab kev suav electromagnetism.

Hauv ntej, ib qho automatic duplex slitter ua haujlwm hauv cov txheej txheem raws li hauv qab no:

1. Tsis Siv Neeg Ntawv Pub-hauv

2. Kev Txiav Ntsug, Kev Sib Hloov thiab Kev Tso, Kev Txiav Kab Rov Tav

3. Kev sau thiab kev teeb tsa

| Qhov ntau zaus | 120-320HZ | Vuam ceev | 6-36m/feeb |

| Muaj peev xwm tsim khoom | 30-200Cans/feeb | Ntau yam ntawm lub qhov taub | Φ52-Φ99mm & Φ65-Φ180mm |

| Qhov siab ntawm lub qhov dej | 55-320 hli | Cov ntaub ntawv siv tau | Tinplate, hlau-raws li, Chrome phaj |

| Cov khoom tuab | 0.16 ~ 0.35 hli | Txoj kab uas hla ntawm cov hlau tooj liab siv tau | Φ1.38mm , Φ1.5mm |

| Dej txias | Kub: ≤20 ℃ Siab: 0.4-0.5Mpa Ntws: 10L / feeb | ||

| Lub zog | 40KVA | Qhov Loj (L * W * H) | 1750 * 1500 * 1800mm |

| Qhov hnyav tag nrho | 1800Kg | Hmoov | 380V ± 5% 50Hz |

Lublub cev tuaj yeem vuam tshuabyog lub plawv ntawm txhua txoj kab tsim khoom peb daim. Nws ua rau lub cev khoob rau hauv lawvcov duab yooj yimthiabwelds qhov seam overlap. Peb lub hauv paus ntsiab lus ntawm Superwima vuam tsuas yog xav tau qhov sib tshooj tsawg kawg nkaus ntawm ob peb feem kaum ntawm ib millimeter. Kev tswj hwm zoo tshaj plaws ntawm qhov tam sim no vuam ua ke nrog qhov siab sib phim ntawm qhov sib tshooj. Txij li thaum pib tsim cov tiam tshiab ntawm cov welders, cov neeg siv khoom thoob plaws ntiaj teb tau lees paub hnub no lawv qhov kev txaus siab ntau ntawm qhov zoo tshaj plaws thiab kev ntseeg siab ntawm lub tshuab ua ke nrog ib qhokev lag luam pheej yigthiab ib qhokev tsim khoom zooCov qauv kev lag luam tshiab tau teeb tsa hauv kev tsim cov canbodies thoob ntiaj teb.

Txheej txheem txheej

Lub tshuab txheej hmoov yog ib qho ntawm cov khoom txheej hmoov uas Changtai Company tau tsim tawm. Lub tshuab no yog mob siab rau cov txheej txheem txau ntawm cov vuam ntawm cov chaw tsim khoom qab zib.

| Qauv | CTPC-2 | Voltage & Zaus | 380V 3L + 1N + PE |

| Kev ceev ntawm kev tsim khoom | 5-60m/feeb | Kev noj hmoov | 8-10 hli & 10-20 hli |

| Kev siv cua | 0.6Mpa | Lub cev muaj peev xwm ntau yam | D50-200mm D80-400mm |

| Qhov yuav tsum tau cua | 100-200L/feeb | Kev siv hluav taws xob | 2.8KW |

| Tshuab qhov ntev | 1080 * 720 * 1820 hli | Qhov hnyav tag nrho | 300kg |

Lub tshuab txheej hmoov yog ib qho ntawm cov khoom txheej hmoov uas Changtai Company tau tsim tawm. Lub tshuab no yog mob siab rau cov txheej txheem txau ntawm cov vuam ntawm cov chaw tsim khoom qab zib.

| Qhov siab ntawm qhov tuaj yeem | 50-600 hli | Qhov ntau thiab tsawg ntawm txoj kab uas hla | 52-400 hli |

| Qhov ceev ntawm cov menyuam | 5-30m/feeb | Hom txheej | Txheej txheej rau cov menyuam |

| Qhov dav ntawm lacquer | 8-15 hli 10-20 hli | Cov khoom siv tseem ceeb & Tam sim no thauj khoom | 220V 0.5 KW |

| Kev siv cua | 0.6Mpa 20L/feeb | Tshuab qhov ntev & Qhov hnyav tag nrho | 2100 * 720 * 1520MM 300kg |

Peb lub tuam txhab siv cov txheej txheem hmoov txheej siab heev, uas ua rau lub tshuab muaj cov qauv tshiab, kev ntseeg siab ntawm lub kaw lus, kev ua haujlwm yooj yim, kev siv dav thiab kev ua tau zoo-tus nqi piv. Thiab kev siv cov khoom tswj hwm txhim khu kev qha, thiab cov davhlau ya nyob twg kov thiab lwm yam khoom, ua rau lub kaw lus ruaj khov thiab txhim khu kev qha dua.

Lub tshuab txheej hmoov siv hluav taws xob zoo li qub los tsuag cov hmoov yas rau ntawm qhov vuam ntawm lub tank lub cev, thiab cov hmoov khov kho raug yaj thiab ziab los ntawm kev cua sov hauv qhov cub kom tsim ib txheej yas tiv thaiv zaj duab xis (polyester lossis epoxy resin) rau ntawm qhov vuam. Vim tias cov hmoov tuaj yeem npog tag nrho thiab sib npaug ntawm cov burrs thiab qhov siab thiab qis ntawm qhov vuam raws li cov duab tshwj xeeb ntawm qhov vuam los ntawm lub hauv paus ntsiab lus ntawm electrostatic adsorption thaum txau, nws tuaj yeem tiv thaiv qhov vuam los ntawm kev xeb ntawm cov ntsiab lus;

Tib lub sijhawm, vim tias cov hmoov yas muaj kev tiv thaiv corrosion siab rau ntau yam tshuaj lom neeg thiab sulfur, acid thiab cov protein ntau hauv cov zaub mov, cov tshuaj tsuag hmoov yog qhov tsim nyog rau ntau yam ntsiab lus sib txawv; Thiab vim tias cov hmoov ntau dhau tom qab txau hmoov siv lub hauv paus ntsiab lus ntawm kev rov ua dua tshiab thiab rov siv dua, tus nqi siv hmoov yog siab, thiab nws yog qhov kev xaiv zoo tshaj plaws rau kev tiv thaiv weld tam sim no.

Lub tshuab txheej seam yog dab tsi thiab nws daim ntawv thov?

Tom qab vuam, sab hauv thiab sab nraud seaming yuav tsum tau coated los ntawm cov txheej tiv thaiv ruaj khov, ces lub weld seam yuav tsis xeb. Lub tshuab txheej lacquer ntub dej yog random collocation rau ntau yam kev xav tau, lub seam sab hauv tuaj yeem yog roller txheej lossis tsuag txheej, lub seam sab nraud tuaj yeem yog roller txheej, tsuag txheej lossis poob txheej. Lub tshuab txheej sab seam yog ntau yam rau weld seam ntawm cov khoom noj khoom haus, cov dej haus thiab cov aerosol cov kaus poom nrog rau cov thawv ntim khoom lag luam. Lub kaus poom txheej yog yooj yim kho thiab siv lacquer tsawg.

Raws li cov tshuaj pleev xim, lub tshuab pleev xim lacquer yog hloov tau, rau sab hauv txheej, Peb tuaj yeem tsim nws ua tshuaj tsuag lossis cov menyuam txheej, rau sab nraud txheej, nws tuaj yeem yog cov menyuam txheej lossis poob txheej. Lub chaw tsim khoom tuaj yeem xaiv cov cuab yeej tsim nyog rau kev sib xyaw ua ke dawb.

Daim Ntawv Thov:

Lub tshuab txheej siv tau dav hauv kev lag luam hlau tuaj yeem tsim khoom, los tiv thaiv cov hlua khi ntawm qhov xeb thiab xeb. Lub tshuab no tsim nyog rau:

1. Kev ua kab dav dav

2. Ua cov khoom noj 3 daim

3. Ua cov aerosol tau

4. Lub thoob yas los yog lub thoob tshuaj ua los ntawm tshuaj lom neeg

5. Lub thoob dej los yog lub thoob dej ua cov tshuaj yaj

6. Ua cov xim pleev xim

Cov tshuab txau ua lub luag haujlwm tseem ceeb hauv kev lag luam tsim cov kaus poom. Los ntawm kev sib koom ua ke ntawm automation, muaj peev xwm ua ntau yam txheej txheem, tsim qauv siv hluav taws xob tsawg, tswj xyuas zoo, thiab cov thev naus laus zis tshiab, cov tshuab no muab cov kev daws teeb meem tsim khoom zoo, txhim khu kev qha, thiab sib tw rau cov chaw tsim cov kaus poom.

Ib lub tshuab ua kom sov lossis lub tshuab ziab rau kev vuam lub cev ntawm lub kaus poom yog ib qho tseem ceeb ntawm cov kab ntau lawm rau kev tsim khoom noj, dej haus, thiab mis hmoov. Nws yog siv los ziab cov kaus poom tom qab txheej lossis luam ntawv, kom ntseeg tau tias cov khoom siv kho thiab lo rau zoo.

Tag nrho cov khoom tsim tau thiab qhov zoo ntawm cov txheej txheem tsim cov kaus poom. nyob rau sab nraub qaum ntawm nws (curing system) muaj peev xwm ziab tau zoo, tswj qhov kub thiab txias kom raug, tsim qauv me me, txuag hluav taws xob, thiab cov yam ntxwv kev nyab xeeb.

| Kev ceev ntawm lub tshuab thauj khoom | 5-30m/feeb | Qhov ntau thiab tsawg ntawm txoj kab uas hla | 52-180 hli |

| Hom kev thauj khoom | Tsav tsheb tiaj tiaj | Cov khoom siv cua txias. coil | Tsis xav tau dej / cua |

| Kev ua kom sov zoo | 800mm * 6 (30cpm) | Cov khoom siv tseem ceeb & Tam sim no thauj khoom | 380V+N>10KVA |

| Hom cua sov | Kev taw qhia | Kev ntsuas qhov deb | 5-20MM |

| Cua Sov Dua | 1KW * 6 (kub teeb tsa) | Qhov taw qhia induction | 40MM |

| Kev teeb tsa zaus | 80KHz + -10KHz | Lub sijhawm pib | 25 vib nas this (410mmH, 40CPM) |

| Electro.Radiation tiv thaiv | Npog nrog cov neeg tiv thaiv kev nyab xeeb | Lub sijhawm sawv (MAX) | Nrug deb 5 hli 6 vib nas this & 280 ℃ |

| Qhov Loj (L * W * H) | 6300 * 700 * 1420mm | Qhov Hnyav Tag Nrho | 850KG |

Changtai muaj ntau yam kev kho kom zoo nkauj uas tsim los ua kom cov txheej tiv thaiv kab sib txuas khov kho. Tom qab siv cov txheej tiv thaiv kab sib txuas lacquer lossis hmoov, lub canbody yuav kho cua sov. Peb tau tsim cov tshuab cua sov modular uas siv roj lossis induction nrog kev tswj qhov kub thiab txias tsis siv neeg thiab cov siv conveyor uas hloov kho qhov ceev. Ob lub tshuab cua sov muaj nyob rau hauv linear lossis U-puab layout.

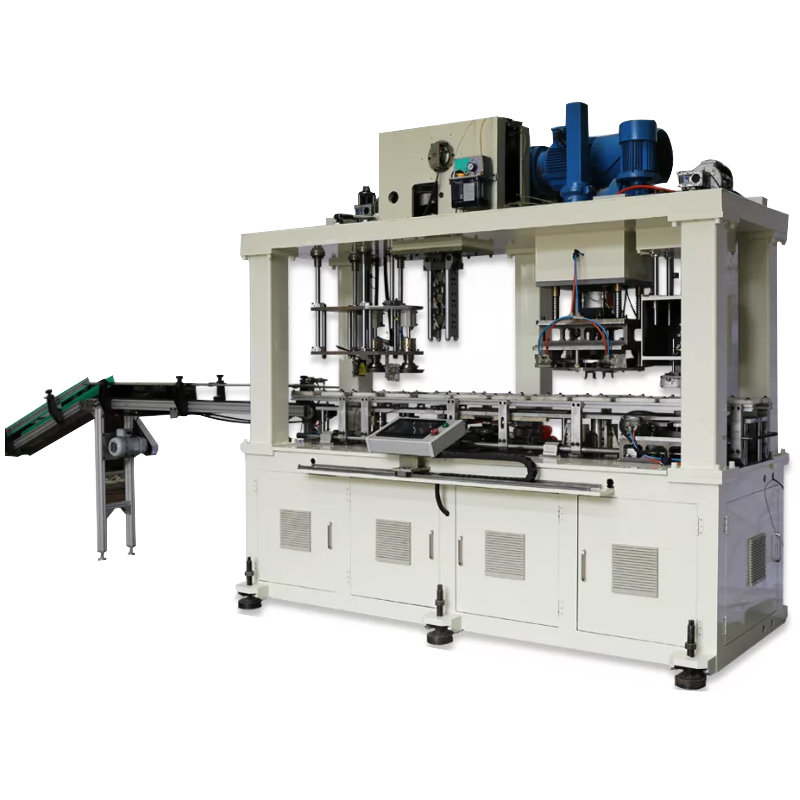

Kev tsim thiab sib dhos ntawm lub cev

Tshuab Ua Ke Canbody

| Muaj peev xwm tsim khoom | 30-35cpm | Qhov ntau thiab tsawg ntawm Can Dia. | 110-190 hli |

| Qhov siab ntawm qhov tuaj yeem | 110-350 hli | tuab | ≤0.4 |

| Lub zog | 26.14kw | Lub zog cua ntawm lub tshuab: | 0.3-0.5Mpa |

| Lub cev tsa lub tshuab nqa khoom loj | 2250 * 230 * 920mm | Qhov loj ntawm cov khoom siv thauj khoom | 1580 * 260 * 920mm |

| Qhov loj ntawm lub tshuab ua ke | 2100 * 1500 * 2340mm | Qhov Hnyav Tag Nrho | 4T |

| Qhov Loj ntawm Carbinet Hluav Taws Xob | 700 * 450 * 1700mm | ||

Tshuab seaming kaus poom tsis siv neeg

| muaj peev xwm tsim khoom | 35cpm |

| kab pheeb ces kaum | 50-190m |

| qhov siab ntawm qhov tuaj yeem | 80-350 hli |

| tuab | ≤0.35 hli |

| tag nrho lub zog | 5.13KW * 2 |

| lub zog cua tshuab: | 0.5Mpa |

| qhov loj ntawm lub tshuab thauj khoom pem hauv ntej | (2740 * 260 * 880mm) * 2 |

| qhov loj ntawm lub tshuab seaming | (1100 * 310 * 950mm) * 2 |

| qhov hnyav ntawm lub tshuab seaming | 2.5T * 2 |

Peb lub tshuab ua kom zoo dua lub kaus poom thiab lub tshuab ua lub cev kaus poom no siv tau rau ntau yam kev siv, suav nrog kev faib, kev ua kom zoo nkauj, kev xaws caj dab, kev sib txuas, kev xaws hlaws thiab kev sib txuas. Nrog kev kho dua tshiab sai thiab yooj yim, lawv ua ke cov khoom tsim tau zoo heev nrog cov khoom zoo tshaj plaws, thaum muab cov kev nyab xeeb siab thiab kev tiv thaiv zoo rau cov neeg teb xov tooj.

Hauv kev ua Tin Can, lub tshuab ua ke,

ua ke cov haujlwm Flanging, Beading Thiab Seaming hauv ib qho txheej txheem.

Lub tshuab ua ke flanging, beading, thiab seaming muab ntau yam kev ua haujlwm sib xyaw ua ke rau kev tsim cov kaus poom. Nws tuaj yeem ua cov txheej txheem ntawm flanging, beading, thiab seaming, ua ke ntau kauj ruam rau hauv ib lub tshuab, txhim kho kev ua haujlwm zoo thiab ua haujlwm tau zoo.

Cov cuab yeej kuaj qhov xau

| Qhov ntau ntawm cov khoom uas tau kuaj pom | 1-5L |

| Cov khoom siv cua siab | 4-6Bar |

| Tshawb xyuas qhov siab | 10-15Kpa |

| Kev kuaj pom qhov tseeb | 0.17 hli |

| Kev ceev ntawm kev tshawb pom | 30PCS/feeb |

| Qhov Hnyav ntawm Lub Tshuab | 1500KG |

| Qhov Loj (L * W * H) | 3200mm * 950mm * 2200mm |

| Lub zog nkag | 380v/50HZ |

Peb muab cov cuab yeej kuaj qhov xau rau txhua qhov loj me thiab cov duab ntawm cov kaus poom thiab rau cov thoob thiab cov nruas ntawm txhua qhov loj me.

Thaum cov thawv hlau lossis cov thawv yas ua tiav los ntawm kab ua cov kaus poom, cov thawv yuav raug xa mus rau hauv lub tshuab kuaj xyuas qhov xau, uas feem ntau hu ua lub tshuab kuaj kaus poom, lub tshuab kuaj pail lossis lub tshuab kuaj nruas nyob ntawm qhov khoom uas pom. Lub tshuab kuaj qhov xau tshuaj xyuas thiab ntes cov thawv los ntawm huab cua, cov thawv tuaj yeem pub ua kab ncaj lossis tig. Rau cov kaus poom lossis pails kab dav dav, qhov ceev ntawm cov kab tsim kaus poom tsis siab heev, nws zoo dua los siv cov qauv ntsuas qhov xau hauv kab ua kab ncaj, thiab rau cov kaus poom aerosol lossis chav me me, nws zoo dua los siv lub tshuab kuaj kaus poom tig.

Lub tshuab palletizing

| Qhov siab ua haujlwm haum rau qhov loj ntawm pallet | 2400 hli |

| qhov loj ntawm pallet tsim nyog | 1100mm × 1400mm; 1000mm x 1200mm |

| Muaj peev xwm tsim khoom | 300 ~ 1500 lub kaus poom / feeb |

| Qhov loj ntawm lub thoob uas siv tau | Txoj kab uas hla 50mm ~ 153mm, qhov siab: 50mm ~ 270mm |

| Cov khoom siv tau | Txhua yam khoom siv tinplate, lub raj mis iav thiab lub raj mis yas |

| Qhov Loj | Ntev 15000mm (tsis muaj zaj duab xis qhwv) × dav 3000mm × siab 3900mm |

| Kev muab hluav taws xob | 3 × 380V 7KW |

Feem ntau cov kab tsim cov thoob yas yuav xaus nrog lub tshuab palletizer. Cov kab sib dhos ntawm lub thoob yas tuaj yeem hloov kho tau, uas yuav ua kom cov pawg khoom uas tuaj yeem palletized hauv cov kauj ruam tom ntej. Qee tus neeg siv khoom tau txais cov neeg ua haujlwm los ua txoj haujlwm no.

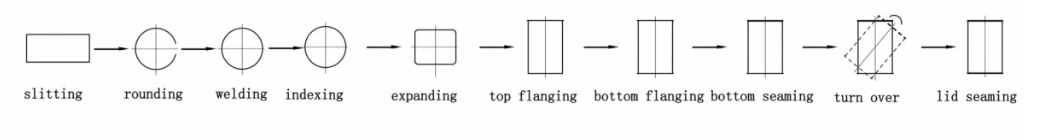

Tin can ua artcraft

1-5Lduab plaub fab daim ntawv qhia txog kev ntws ntawm cov can

Cov Ntaub Ntawv Txog Lub Tuam Txhab

Pib xyoo 2007, Chengdu Changtai tau mob siab rau kev tsim tshuab ua cov kaus poom tau 20 xyoo, tam sim no tau dhau los ua lub tuam txhab thev naus laus zis siab heev hauv tebchaws uas muaj ntau dua kaum daim ntawv pov thawj tsim khoom. Peb muaj pab pawg neeg ua haujlwm zoo tshaj plaws ntawm cov kws ua haujlwm thiab cov kws tshaj lij nrog kev paub dhau los hauv kev tsim cov kaus poom peb-daim thiab nrog rau kev tshawb fawb thiab kev siv cov khoom siv kho qhov muag, digital, hluav taws xob hauv cov tshuab ua kaus poom. Los ntawm ISO9001, SGS thiab BV daim ntawv pov thawj, ua rau nws yog lub npe nrov ua tshuab ua kaus poom hauv Suav teb.

Tiv tauj rau kev nug txog cov tshuab