Lub tshuab chiller rau kev lag luam ua kua txiv hmab txiv ntoo

Lub tshuab chiller rau kev lag luam ua kua txiv hmab txiv ntoo

Cov Kev Ntsuas Kev Txawj

| Pawg | Chav tsev | Qhov ua tau zoo | |

| Muaj peev xwm txias tau | 50HZ | KW | 100 |

| Kcal/teev | 126000 | ||

| Lub hwj chim nkag | 380V-50Hz | ||

| Lub tshuab cua txias | Pawg | Hom vortex | |

| Lub zog / KW | 30 | ||

| Lub qhov cua valve | Emerson Thermal Expansion Valve | ||

| Cov tshuaj txias | R 22 | ||

| Condenser | duab | Hom tooj liab fin | |

| Qhov ntim cua txias | M³/teev | 32400 | |

| Lub tshuab ua kom sov | Hom | Tooj liab plhaub thiab raj hom | |

| Txoj kab uas hla ntawm cov yeeb nkab nkag thiab tawm | nti | 2 | |

| Qhov hnyav ntawm lub tshuab | KG | 1450 xyoo | |

Kev Taw Qhia Txog Khoom

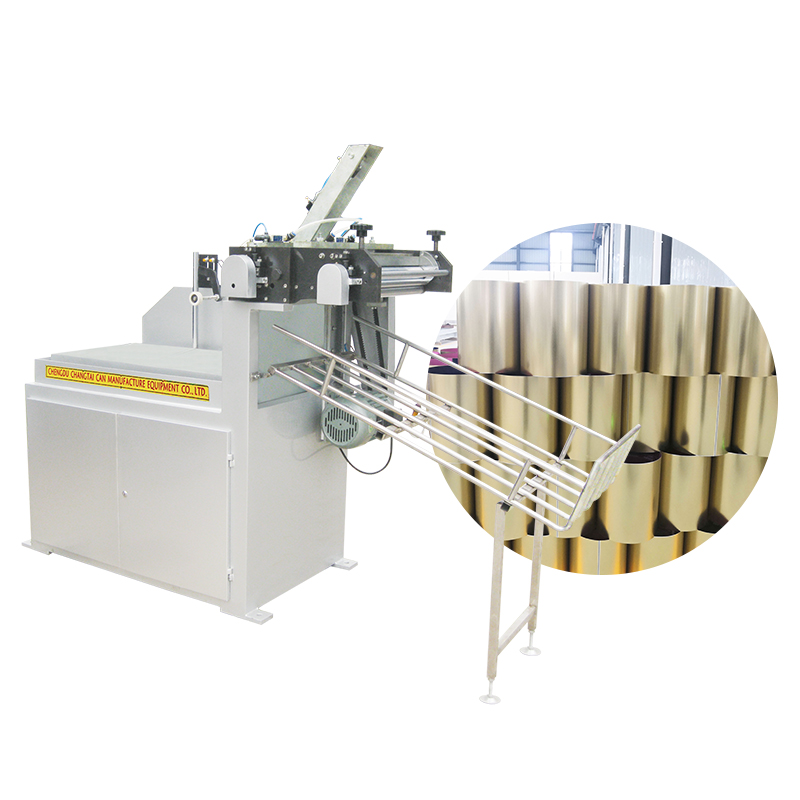

1. Lub tshuab cua txias rau kev lag luam los ntawm Chengdu Changtai Intelligent Equipment Co., Ltd., yog lub tshuab cua txias siab heev uas tsim los rau kev lag luam ua cov kaus poom.

2. Kev sib koom ua ke ntawm cov thev naus laus zis tshiab los ntawm ob qho tib si hauv tsev thiab thoob ntiaj teb, cov khoom tshiab no yog tsim los ua kom tau raws li qhov xav tau ntawm cov chaw tsim khoom rau cov tshuab ua kom txias zoo thiab txhim khu kev qha.

3. Los ntawm kev tswj qhov kub kom raug, lub tshuab txias no ua rau cov khoom zoo thiab kev ua haujlwm tau zoo dua qub thaum txo cov nqi tsim khoom, thiab thaum kawg ua rau cov lag luam tau txiaj ntsig ntau dua.

Daim Ntawv Thov Hauv Kev Lag Luam Ua Taub Hau:

Hauv cov txheej txheem tsim cov kaus poom xws li kev txhaj tshuaj molding, kev nqus, thiab kev tshuab molding, kev txias yog kwv yees li 80% ntawm lub sijhawm tsim khoom. Peb lub tshuab txias kev lag luam muab kev tswj qhov kub kom raug, txo qhov kub ntawm pwm kom ruaj khov thiab ua kom sai dua. Qhov no txo cov voj voog tsim khoom, tiv thaiv kev hloov pauv thiab kev ntsws, thiab txhim kho cov khoom pob tshab thiab meej. Kev tswj qhov kub zoo dua kuj txo qhov nrawm ntawm cov khoom puas.

Cov txiaj ntsig

▲ Kev Tswj Kub Kom Tseeb: Tswj tau qhov zoo ntawm cov khoom thiab txo qhov tsis zoo.

▲ Kev Ua Haujlwm Zoo Dua: Ua kom luv luv ntawm cov voj voog tsim khoom thiab ua kom cov txheej txheem tsim khoom sai dua.

▲ Txo Nqi: Txo kev siv hluav taws xob thiab txo cov khib nyiab, ua rau muaj txiaj ntsig ntau dua.

▲ Kev Siv Tau Ntau Yam: Hloov tau rau ntau yam lag luam nrog cov kev xaiv hloov kho tau rau cov kev xav tau tshwj xeeb.

▲ Eco-Friendly: Txhawb kev siv tshuaj lom neeg dua tshiab, txo qhov cuam tshuam rau ib puag ncig.

1. Peb lub tuam txhab kawm los ntawm cov tshuab hauv tsev thiab txawv teb chaws, thiab tsim cov koob tshiab ntawm cov tshuab txias kev lag luam kom tau raws li cov neeg siv khoom xav tau, nrog rau kev tswj qhov kub thiab txias kom meej, txhim kho cov khoom zoo thiab kev tsim khoom, txo tus nqi ntau heev thiab nce cov nyiaj tau los.

2. Thaum lub sijhawm txhaj tshuaj, nqus thiab tshuab yas, qhov txias siv sijhawm 80% ntawm lub sijhawm tsim khoom. Lub tshuab dej txias tuaj yeem tswj qhov kub kom raug thiab txo qhov kub ntawm chav tsev thiab ruaj khov thiab ua kom sai dua, lub voj voog tsim khoom luv dua kom tsis txhob deform thiab ntsws, ua rau cov khoom pob tshab thiab meej. Cov khoom pov tseg yuav raug txo qis ntau los ntawm kev txhim kho kev tswj qhov kub.

3. Lub tshuab ua dej txias yuav txo qhov kub ntawm cov kua electroplate thiab ua kom cov hlau thiab cov hlau tsis ruaj khov nrog rau lub zog hluav taws xob ruaj khovntawm qhov chaw sai sai, thiab ua rau kom cov electroplate ceev thiab du, thiab txhim kho qhov zoo thiab txo cov sijhawm galvanization thiab lub sijhawm tsim khoom. Lub caij no, txhua yam tshuaj lom neeg kim tuaj yeem rov ua dua tshiab tau yooj yim thiab ua haujlwm tau zoo. Lub tshuab tuaj yeem siv rau hauv kev lag luam nqus tsev metallization.

4. Dhau li ntawm qhov saum toj no, cov koob no ntawm cov tshuab dej txias tau siv dav rau cov khoom noj khoom haus, hluav taws xob, tshuaj lom neeg, sauna, nuv ntses, tshuaj pleev ib ce, tawv cuav, chaw kuaj mob, thiab lwm yam. Thiab qee cov koob tshwj xeeb muaj rau optical disc, hluav taws xob sparking tshuab, ultrasonic machinery kev lag luam, uas muaj cov khoom ntawm acid-resistant thiab alkali-resistant.

Yog xav paub ntxiv txog lub chaw tsim khoom siv Can

Yog xav paub ntxiv txog tus nqi thiab cov kev pabcuam, thov nias ntawm no>>>Tiv tauj peb

--------

Yog xav paub ntxiv txog peb lub tuam txhab, thov nias ntawm no >>>Txog peb

--------

Yog xav paub ntxiv txog peb cov ntaub ntawv, thov nias ntawm no >>>Peb Cov Khoom

--------

Yog xav paub ntxiv txog peb cov AfterSales thiab lwm tus neeg kuj nug cov lus nug, thov nyem qhov no >>>Cov Lus Nug Feem Ntau