Lub luag haujlwm ntawm Advanced Vuam thiab Slitting Tshuab hauv Tin Can Manufacturing

Hauv cov khoom ntim khoom noj thiab dej haus, cov kaus poom tseem yog cov khoom tseem ceeb vim lawv cov khoom siv ua haujlwm ntev, kev ua tau zoo, thiab muaj peev xwm khaws cov ntsiab lus. Cov txheej txheem ntawm kev tsim cov kaus poom, txawm li cas los xij, tau hloov pauv ntau xyoo dhau los, nrog kev nce qib hauv kev siv thev naus laus zis ua kom muaj txiaj ntsig zoo thiab meej. Nyob rau hauv lub plawv ntawm niaj hnub tin tuaj yeem tsim khoom yog cov khoom tseem ceeb xws li tsis siv neeg lub cev vuam tshuab, tinplate slitting riam, thiab tsis siv neeg trimming tshuab, uas ua kom cov khoom tiav zoo.

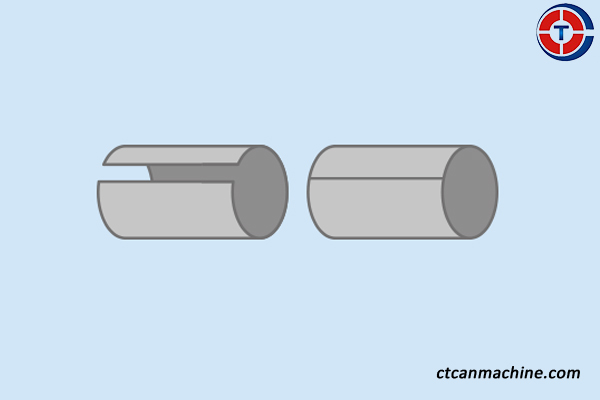

Ib qho kev txhim kho tseem ceeb tshaj plaws hauv cov tin tuaj yeem tsim kab yog qhov tsis siv neeg tuaj yeem lub cev vuam tshuab. Cov tshuab no ua lub luag haujlwm tseem ceeb hauv kev koom nrog lub cev cylindrical ntawm lub peev xwm los ntawm kev vuam cov hlau seams, feem ntau siv cov ntaub ntawv xws li tinplate, hlau phaj, chrome phaj, galvanized phaj, thiab stainless hlau. Niaj hnub nimno vuam tshuab los ntawm cov tuam txhab xws li Changtai Intelligent yog tsim los rau kev ceev thiab precision, nce throughput thiab txo qhov kev pheej hmoo ntawm qhov tsis xws luag. Cov tshuab no yog programmed los txuas cov seams nrog cov neeg siab, uas yog qhov tseem ceeb rau kev ua kom muaj kev ncaj ncees ntawm lub peev xwm.

qhov zoo tseem ceeb

Covtsis siv neeg lub cev vuam tshuabmuaj ntau qhov zoo tshaj plaws uas ua rau nws yog ib qho tseem ceeb ntawm cov khoom siv niaj hnub tuaj yeem tsim khoom:

● Kev Ua Haujlwm Ntau Lawm: Tsis siv neeg vuam tshuab txo lub sijhawm yuav tsum tau koom nrog cov ntawv hlau, ua kom tag nrho cov txheej txheem ntau lawm ceev. Qhov no ua rau cov tuam txhab tsim cov ntim loj hauv lub sijhawm luv, txhim kho kev ua haujlwm thiab ua tau raws li qhov xav tau ntau dua.

● High Precision thiab Consistency: Cov tshuab no yog tsim los rau kev sib txuas ntawm cov hlau seams, kom ntseeg tau tias muaj qhov sib xws thiab zoo ib yam weld hla txhua lub kaus poom. Qhov tseeb ntawm cov tshuab vuam tsis siv neeg tuaj yeem pab tshem tawm qhov tsis xws luag xws li cov seams tsis muaj zog lossis tsis sib xws, uas tuaj yeem cuam tshuam cov qauv kev ncaj ncees ntawm cov kaus poom.

● Txo Cov Nqi Ua Haujlwm: Txij li cov txheej txheem yog automated, qhov xav tau ntawm kev siv tes ua haujlwm tau txo qis heev. Qhov no tsis tsuas yog txo cov nqi zog tab sis kuj txo qis tib neeg kev ua yuam kev, ua rau muaj kev tsim khoom zoo ib yam. Cov neeg ua haujlwm tsuas yog yuav tsum tau saib xyuas lub tshuab, uas txo qhov kev pheej hmoo ntawm kev ua yuam kev thiab kev sib tsoo.

● Kev Siv Hluav Taws Xob: Cov tshuab vuam niaj hnub no feem ntau tsim los nrog cov yam ntxwv txuag hluav taws xob uas ua kom zoo rau kev siv hluav taws xob thaum lub sij hawm vuam. Qhov no txo cov nqi khiav lag luam thiab pab txhawb kev tsim khoom lag luam zoo dua qub.

● Txhim Kho Kev Tswj Xyuas Zoo: Nrog cov yam ntxwv siab heev xws li kev tshuaj xyuas thiab tswj cov tshuab, cov tshuab no tuaj yeem kuaj xyuas qhov tsis xws luag thaum lub sijhawm tsim khoom, kom ntseeg tau tias tsuas yog cov kaus poom ua tau raws li cov qauv kev ua tau zoo txav mus rau theem tom ntej ntawm cov txheej txheem. Qhov kev soj ntsuam tas li no txhim kho qhov zoo ntawm tag nrho cov khoom tiav.

● Cov Nqi Them Nqi Them Nqi: Ntau lub tshuab vuam tsis siv neeg yog tsim nrog cov khoom siv ruaj khov, cov khoom zoo uas yuav tsum tau muaj kev saib xyuas tsawg dua piv rau cov laus, phau ntawv qauv. Kev kuaj mob tsis tu ncua kuj tseem tuaj yeem pab txheeb xyuas cov teeb meem muaj peev xwm ua ntej lawv ua rau poob qis lossis raug nqi kho.

● Kev sib xyaw ua ke nrog lwm cov khoom siv: Cov tshuab vuam no tuaj yeem ua haujlwm seamlessly rau hauv cov kab ntau lawm, ua haujlwm nrog lwm cov tshuab xws li slitting machine, trimming machinery, thiab cov khoom siv txheej. Qhov no tsim cov txheej txheem ntau lawm, ua kom muaj txiaj ntsig zoo uas txo cov fwj thiab txhim kho cov khoom siv.

● Flexibility rau Customization: Ntau yam tsis siv neeg tuaj yeem siv lub cev vuam tshuab tuaj yeem hloov kho kom haum raws li qhov sib txawv thiab qhov tshwj xeeb. Qhov kev hloov pauv no ua rau nws yooj yim rau kev hloov kho ntau lawm kom tau raws li cov kev xav tau ntawm kev lag luam, txawm tias cov khoom me me lossis cov khoom loj loj.

Tsis siv neeg tuaj yeem lub cev vuam tshuab muab ntau yam txiaj ntsig uas txhim kho kev ua haujlwm, txo cov nqi, thiab txhim kho cov khoom zoo, ua rau lawv yog ib qho tseem ceeb hauv kev tsim khoom niaj hnub.

Tom qab cov txheej txheem vuam, cov ntawv hlau yog tom qab ntawd raug rau slitting los tsim cov strips nqaim uas yuav ua rau lub cev cylindrical. Tinplate slitting riam yog qhov tseem ceeb nyob rau hauv cov kauj ruam no, txiav cov hlau los xij nrog precision precision. Qhov zoo ntawm cov riam no, feem ntau ua los ntawm cov ntaub ntawv qib siab zoo li carbide, cuam tshuam ncaj qha rau qhov tseeb ntawm cov txheej txheem slitting thiab tag nrho cov khoom zoo ntawm lub cev. Cov tuam txhab xws li Huxin Cemented Carbide tshwj xeeb hauv kev tsim cov hniav carbide, uas paub txog lawv qhov ntse, hnav tsis kam, thiab lub neej ntev.

Ua ke, cov thev naus laus zis no ua kom cov tin tuaj yeem ua cov txheej txheem tsim khoom, tso cai rau cov tuam txhab tsim cov kaus poom zoo ntawm qhov nrawm nrawm. Raws li cov neeg siv khoom xav tau kev ntim khoom txhim khu kev qha thiab ruaj khov, kev lag luam tseem pheej nqis peev hauv cov tshuab txiav-ntug uas ua kom muaj txiaj ntsig zoo thiab raug. Los ntawm vuam mus rau slitting thiab trimming, kev siv cov cuab yeej siv siab heev hauv tin tuaj yeem tsim yog paving txoj hauv kev rau lub sijhawm tshiab ntawm kev ntim khoom.

Tuam Tshoj ua tus muab kev pabcuam3 daim Tin Can Ua TshuabthiabAerosol tuaj yeem ua tshuab.

Changtai Intelligent Equipment Co., Ltd.yog ib qho kev paub txog Kev Ua Tshuab Hoobkas.Nrog rau kev sib faib, sib dhos, caj dab, flanging, beading thiab seaming, Peb tuaj yeem ua cov tshuab ua kom muaj qib siab modularity thiab txheej txheem muaj peev xwm thiab tsim nyog rau ntau yam kev siv,

Nrog ceev ceev, yooj yim retooling, lawv muab cov khoom tsim tau zoo heev nrog cov khoom zoo tshaj plaws, thaum muab kev nyab xeeb siab thiab kev tiv thaiv zoo rau cov neeg ua haujlwm.

Paub ntau ntxiv

Yog xav paub ntxiv txog tus nqi thiab kev pabcuam, thov nyem qhov no >> >>Tiv tauj peb

--------

Yog xav paub ntxiv txog peb Lub Tuam Txhab, thov nyem qhov no >> >>Hais txog peb

--------

Yog xav paub ntxiv txog peb cov ntaub ntawv, thov nyem qhov no >> >>Peb Cov Khoom

--------

Kom paub ntau ntxiv txog peb AfterSales thiab lwm tus neeg kuj nug cov lus nug, thov nyem qhov no >> >>FAQ

--------

Saib cov khoom >> >>Link: tuaj yeem ua cov khoom siv ...

Post lub sij hawm: Jun-12-2025