Cov kauj ruam hauv cov txheej txheem ntim cov tais rau zaub mov Peb-thooj poom:

1. Muaj peev xwm Manufacturing

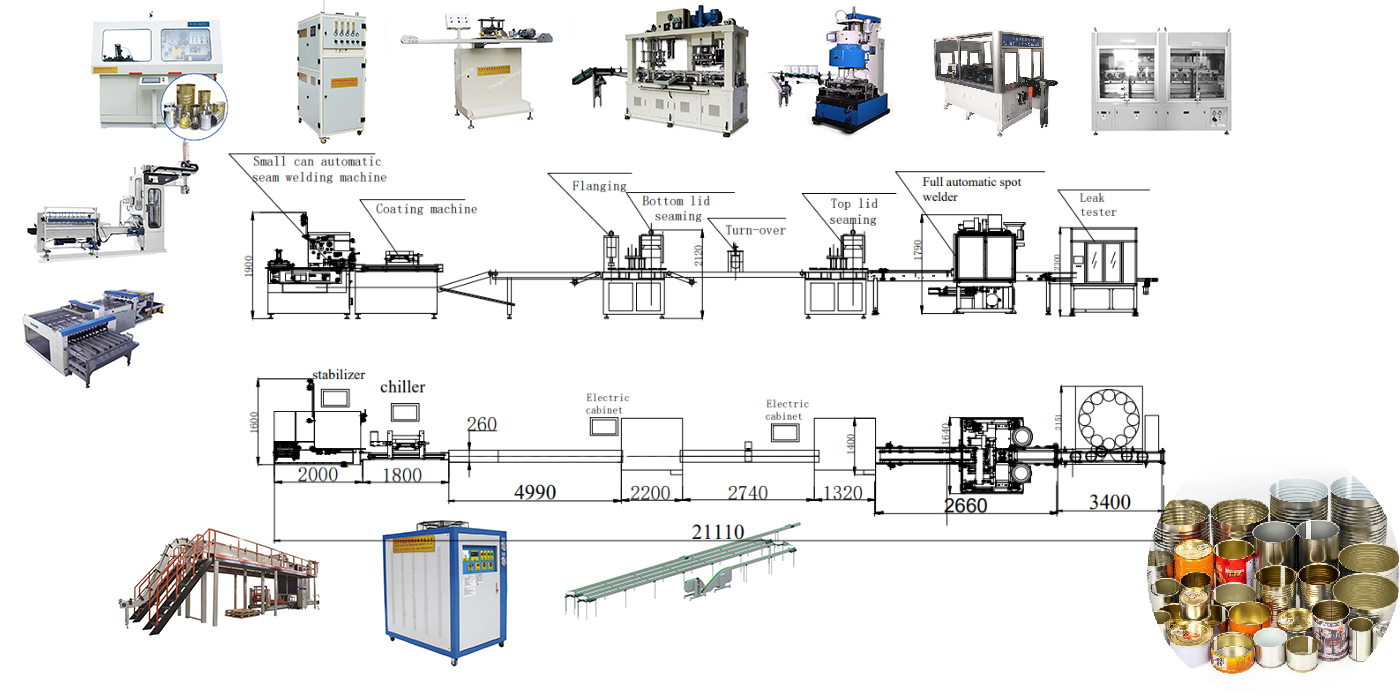

Thawj kauj ruam hauv cov txheej txheem yog tsim peb-thooj cov kaus poom, uas muaj ob peb kauj ruam hauv qab no:

- Lub Cev Ntau Lawm: Ib daim ntawv ntev ntawm cov hlau (feem ntau yog tinplate, aluminium, lossis steel) yog muab rau hauv lub tshuab uas txiav nws mus rau hauv cov duab plaub lossis cylindrical. Cov ntawv no ces dov mus rau hauvcylindrical lub cev, thiab cov npoo yog welded ua ke.

- Hauv qab Tsim: Hauv qab ntawm lub kaus poom yog tsim los ntawm cov hlau tsis muaj hlau uas yog stamped los yog sib sib zog nqus kos kom haum rau txoj kab uas hla ntawm lub kaus mom lub cev. Hauv qab yog ces txuas rau lub cev cylindrical siv ib txoj kev xws li ob chav seaming los yog vuam, nyob ntawm seb tus tsim.

- Sab saum toj Tsim: Lub hau sab saum toj kuj tsim los ntawm cov ntawv hlau tiaj tus, thiab nws feem ntau txuas nrog lub cev tuaj yeem tom qab hauv cov txheej txheem ntim khoom tom qab cov zaub mov tau ntim rau hauv lub kaus poom.

2. Ntxuav thiab Sterilization ntawm cov kaus poom

Thaum cov kaus poom peb-thooj tau tsim, lawv raug ntxuav kom huv si kom tshem tawm cov khoom seem, roj, lossis cov khoom paug. Qhov no yog ib qho tseem ceeb los xyuas kom meej qhov kev ncaj ncees ntawm cov zaub mov sab hauv thiab tiv thaiv kev sib kis. Cov kaus poom feem ntau sterilized siv chav lossis lwm txoj hauv kev kom paub tseeb tias lawv muaj kev nyab xeeb rau kev siv khoom noj.

3. Kev npaj lub tais

Nyob rau hauv lub tais ntim txheej txheem,cov tais or cov thawvnpaj los tuav cov kaus poom ua ntej lawv ntim cov zaub mov. Cov tais tuaj yeem ua los ntawm cov khoom siv xws li duab los qhia, yas, lossis hlau. Cov tais yog tsim los khaws cov kaus poom thiab tiv thaiv kev puas tsuaj thaum thauj. Rau qee cov khoom, cov tais yuav muaj cov khoom sib cais los cais cov khoom sib txawv lossis hom zaub mov.

4. Kev npaj zaub mov thiab sau

Cov khoom noj khoom haus (xws li zaub, nqaij, kua zaub, los yog cov khoom noj uas npaj txhij) yog npaj thiab siav yog tias tsim nyog. Piv txwv li:

- Zaubtej zaum yuav blanched (ib nrab siav) ua ntej muab cov kaus poom.

- Nqaijtej zaum yuav siav thiab seasoned.

- Kua zaub los yog stewstuaj yeem npaj thiab sib xyaw.

Thaum cov zaub mov tau npaj lawm, nws raug pub rau hauv cov kaus poom los ntawm lub tshuab filling tsis siv neeg. Cov kaus poom feem ntau yog ntim rau hauv ib puag ncig uas ua kom muaj kev nyiam huv thiab kev nyab xeeb ntawm zaub mov raws li cov qauv. Cov txheej txheem filling yog ua raws li kev tswj xyuas qhov kub thiab txias kom muaj kev ruaj ntseg ntawm cov khoom noj.

5. Sealing cov kaus poom

Tom qab cov kaus poom ntim cov zaub mov, lub hau saum toj kawg nkaus muab tso rau ntawm lub kaus poom, thiab lub kaus poom tau kaw. Muaj ob txoj hauv kev tseem ceeb rau kev sib khi lub hau rau lub cev ntawm lub kaus poom:

- Ob chav Seaming: Qhov no yog txoj hauv kev tshaj plaws, qhov twg ntug ntawm lub cev tuaj yeem thiab lub hau yog dov ua ke los ua ob txoj hlua. Qhov no ua kom lub peev xwm kaw kom nruj, tiv thaiv kom tsis txhob tawm thiab ua kom cov zaub mov tseem tiv thaiv.

- Soldering los yog Vuam: Qee zaum, tshwj xeeb tshaj yog nrog qee hom hlau, lub hau yog welded lossis soldered rau ntawm lub cev.

Nqus Sealing: Qee zaum, cov kaus poom yog lub tshuab nqus tsev, tshem tawm cov huab cua los ntawm sab hauv lub kaus poom ua ntej muab khi los txhim kho lub txee lub neej ntawm cov khoom noj.

6. Sterilization (Retort Processing)

Tom qab cov kaus poom raug kaw lawm, lawv feem ntau tau txais ib qhoretort txheej txheem, uas yog ib hom kev ua kom tsis muaj menyuam kub. Cov kaus poom tau rhuab nyob rau hauv ib tug loj autoclave los yog siab cooker, qhov chaw uas lawv raug kub kub thiab siab. Cov txheej txheem no tua cov kab mob lossis kab mob, ua kom lub neej txee ntawm cov zaub mov thiab ua kom nws muaj kev nyab xeeb. Qhov ntsuas kub thiab lub sij hawm yog nyob ntawm seb hom zaub mov uas nyob hauv kaus poom.

- Chav da dej Retort: Nyob rau hauv txoj kev no, cov kaus poom yog submerged hauv dej kub los yog chav thiab rhuab mus rau qhov kub ntawm ib ncig ntawm 121 ° C (250 ° F) rau ib lub sij hawm teem, feem ntau 30 mus rau 90 feeb, nyob ntawm seb cov khoom.

- Siab ua noj: Cov tshuab hluav taws xob siab lossis cov khoom siv hluav taws xob pab xyuas kom cov khoom noj hauv cov kaus poom tau siav rau qhov xav tau kub yam tsis muaj kev cuam tshuam zoo.

7. Txias thiab ziab

Tom qab cov txheej txheem retort, cov kaus poom tau txias sai heev uas siv cov dej txias los yog cua txias kom tsis txhob overcooking thiab xyuas kom lawv ncav cuag qhov kub thiab txias rau kev tuav. Tom qab ntawd cov kaus poom tau qhuav kom tshem tawm cov dej los yog cov dej noo uas tuaj yeem khaws tau thaum lub sijhawm ua kom tsis muaj menyuam.

8. Labeling thiab Ntim

Thaum cov kaus poom txias thiab qhuav, lawv tau sau nrog cov ntaub ntawv cov khoom, cov khoom noj khoom haus, hnub tas sij hawm, thiab cov khoom lag luam. Cov ntawv sau tuaj yeem siv ncaj qha rau hauv cov kaus poom los yog luam tawm rau cov ntawv sau ua ntej thiab qhwv ib ncig ntawm cov kaus poom.

Tom qab ntawd cov kaus poom tau muab tso rau hauv cov tais npaj los yog lub thawv rau kev thauj mus los thiab muag muag. Cov tais pab tiv thaiv cov kaus poom los ntawm kev puas tsuaj thiab ua kom yooj yim tuav thiab ntim khoom thaum thauj khoom.

9. Kev Tswj Xyuas Zoo thiab Kev Tshawb Fawb

Cov kauj ruam kawg suav nrog kev tshuaj xyuas cov kaus poom kom paub tseeb tias tsis muaj qhov tsis xws luag, xws li cov kaus poom dented, xoob seams, los yog xau. Qhov no feem ntau yog ua los ntawm kev tshuaj xyuas qhov muag, kev ntsuas siab, lossis kev ntsuas lub tshuab nqus tsev. Qee cov tuam txhab lag luam kuj tseem ua cov qauv ntsuas ntsuas rau tej yam xws li saj, kev ntxhib los mos, thiab khoom noj khoom haus zoo kom ntseeg tau tias cov zaub mov sab hauv yog raws li tus qauv.

Cov txiaj ntsig ntawm lub tais ntim rau zaub mov Peb-thooj poom:

- Kev tiv thaiv: Cov kaus poom muab lub zog tiv thaiv kev puas tsuaj rau lub cev, ya raws, thiab cov kab mob, ua kom cov zaub mov nyob twj ywm tshiab thiab nyab xeeb rau lub sijhawm ntev.

- Kev khaws cia: Lub tshuab nqus tsev sealing thiab sterilization txheej txheem pab khaws cov khoom noj qab zib, kev ntxhib los mos, thiab cov khoom noj khoom haus thaum txuas nws lub neej txee.

- Cia Efficiency: Cov duab zoo ib yam ntawm cov kaus poom tso cai rau kev khaws cia kom zoo thiab muab tso rau hauv cov tais, uas ua kom qhov chaw zoo tshaj plaws thaum lub sijhawm thauj mus los thiab cov khoom muag muag.

- Consumer Convenience: Peb-thooj cov kaus poom tau yooj yim qhib thiab tuav, ua rau lawv muaj kev xaiv ntim yooj yim rau cov neeg siv khoom.

Zuag qhia tag nrho, cov txheej txheem ntim cov tais rau cov zaub mov hauv peb lub kaus poom kom cov khoom noj muaj kev nyab xeeb, khaws cia, thiab npaj rau kev faib tawm thaum tswj xyuas qhov zoo thiab kev ncaj ncees ntawm cov khoom sab hauv.

Post lub sij hawm: Nov-25-2024